Types of Screws – Our Very Comprehensive Guide to Fasteners

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

While glues and adhesives have come a long way since their inception, sometimes you need something a little bit more solid to hold your workpiece together. This is where fasteners come into play. Fasteners are characterized as anything that allows you to close or secure something in a semi-permanent manner. This being said, fasteners are used in almost every industry around the world for different applications, but since their inception, they have come a long way. Modern fasteners are made of highly durable and weather-resistant materials, and also happen to be a lot cheaper than their predecessors. If you’re in the process of renovating your home or happen to be thinking about it, you should familiarize yourself with some of the fasteners you may encounter on your journey. This is why we’ve prepared a short list of common (and not so common) fasteners you might encounter on your journey.

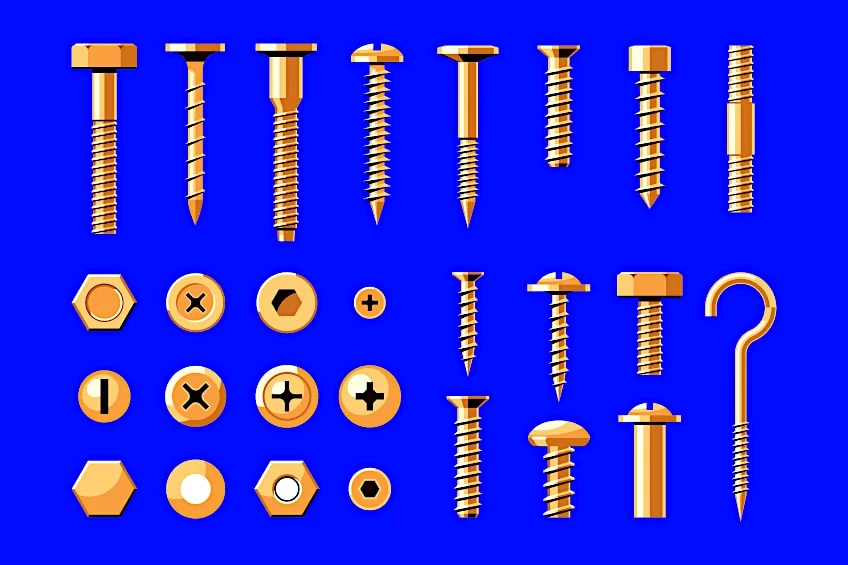

Screws and Screwheads

What are screws? Screws are defined as a slim, short piece of metal that has a raised helical thread capable of penetrating and/or tapping into a given surface. The head of a screw can have widely varying drive configurations and can be used for a number of applications both in the home and commercially. The types of screws you might find yourself using typically depend on the material you’re working with but considering the obscene amount and different types of screws available these days their applications tend to overlap at certain points.

Wood Screws

If you’re unable to or simply don’t want to use adhesives with your wooden workpiece then wood screws are a great way to go. Wood screws are self-tapping which means you don’t have to pre-drill a hole for your screw. They are also available in two drive configurations, namely slotted (flat head) and Philips head (star-shaped). These are arguably the most used fasteners in day-to-day life.

Machine Screws/Bolts

If you’ve ever worked on a car, motorcycle, or any other type of machine then you’ve probably encountered these before. Although they’re being swapped out for hard-wearing plastic clips these days, machine screws/bolts are threaded into pre-tapped holes in machines or mechanical fasteners such as cylinder heads, or hose clamps. They’re about as common as wood screws and are a dime a dozen!

Thread Forming Machine Screws/Bolts

As you’ve probably put together by the name, these screw types are capable of cutting their own internal thread in a workpiece. While they can be used on a wooden workpiece, in theory, they are usually reserved for a metal workpiece that requires a self-tapping bolt that is easy to remove. They are countersunk which leaves the surface of your workpiece flush and are available in both slotted and Phillips head drive configurations.

Sheet Metal Screws

As the name implies sheet metal screws are used to connect and/or fasten sheet metal either to itself or to another workpiece. These screws are self-tapping which means you don’t have to pre-drill any holes to thread them in. These screw types are available in two drive configurations, namely Philips head and slotted so no special tools are needed to fir them either.

Self-Drilling DMS

These are pretty much one of the most versatile screws you can find. As the name implies these screws are self-drilling and tapping which means you won’t have to prepare a recess for them to slot into. They are typically used to fasten metal to metal, or even metal to wood if that’s what you find yourself needing to do. They are available in external hex, slotted, and Philips head configurations.

Hex Bolts

Hex bolts are typically found on machinery and are rarely used on wood unless it’s to secure really large and/or heavy lumber. If you have exposed beams in your basement or attic you’ve probably seen a few of these. They can be used to fasten metal to metal, wood to metal, or wood to wood. These are found in the hex drive configuration exclusively. You will need a spanner to tighten or loosen these, as opposed to a screwdriver.

Carriage Bolts

Carriage bolts are a bit weird and aren’t a common sight in everyday life. These bolts have a completely flush head with no drive configuration. Instead, they have a hex drive on the neck of the bolt which is used to secure the fastener. These bolts are used to secure metal to wood or metal to metal in certain industries where their characteristics are needed.

Lag Bolts

Lag bolts are pretty unique in terms of screw types and sizes. These are heavy-duty fasteners that are used to secure really big and heavy pieces of lumber to one another. Lag bolts are self-tapping and are unique as the shaft of the bolt is only threaded two-thirds of the length with the remaining length (close to the head) being completely smooth.

Socket Screws/Bolts

Have you ever found yourself working with a bolt or screws and the material you’re trying to penetrate is so tough that you end up stripping the thread or warping the head? Well, this is why socket screws exist. Since they’re designed to be used with a quarter-inch ratchet they have more stress points and are therefore able to tolerate more torque both at the head and on the thread.

Set Screws/Bolts

Set screws or Allen head screws are an interesting and unique type of fastener. They’re usually used to sit flush with the surface of a workpiece and are really small too. They have an internal hex drive configuration and are usually used to join shafts, tensioners, or pulley systems. These can be tricky to work with especially if they’re worn out, so be careful.

Eye Bolts

While most of the fasteners we’ve looked at previously have been designed for use with wood and metal, the eye bolt is typically used with brick and masonry surfaces. Once a hole has been tapped the bolt can be tapped in and used to secure ropes and pulley systems. These bolts can be used on wood and metal too, just be sure to check their stress rating to ensure they’re suitable for your intended application.

Eye Lags

Eye lags are essentially the same as eye bolts with the key difference being that they have a slot for things like ropes and ties to be slotted into the hoop. They also differ from eye bolts in that they are primarily used on wood instead of metal and masonry. To better equip them for this application they are self-tapping, although an internal thread can be tapped to assist with their entry.

J-Bolts

J-bolts are easy to identify thanks to them being shaped like the letter J. These are pretty common in some construction applications and are used to support various things. They are typically used to tap through a surface, with a nut on each side of the surface used to fix them in position. These are not self-tapping, so holes or internal threads will need to be made before these can be inserted.

U-Bolts

Much like the J-bolt, the U-bolt is basically just a long bolt that has been fashioned to resemble the letter U. What are these fasteners used for? Well, they’re usually fixed around piped to prevent them from swinging around and are rarely used to tap into a surface. They also have a clamp that spans the length of the open end to secure piping or any other applicable material.

Shoulder Bolts

Shoulder bolts are used in assemblies where mounting pins, joints, shafts, or a pivoting or sliding motion is required. The smooth part of the shaft allows free movement. Also called an axle bolt, the function is to allow for rotation of any part secured to the threaded section.

Elevator Bolts

Elevator bolts, as the name suggests, are usually used in elevators and any other mechanism designed to lift things up like conveyor belts and lifts. These are characterized as having a completely flat head that is designed to sit flush with the surface of a workpiece. The drive configuration is located underneath the head of the bolt and is usually hex-shaped, which means they are fastened from the other end of the workpiece.

Sex Bolts and Mating Screws

Sex bolts – also known as axial barrel nuts – are the receiving half of a two-part fastening team. These bolts are cool because they’re really difficult to remove once they have been put in place. It is for this reason that they are usually used for applications where security is a problem. It comes as no surprise then that they are used to fasten security gates like the slam-lock ones. Mating screws are usually used in conjunction with a sex bolts.

Hanger Bolts

Hanger bolts are as much a fastening mechanism as they are a means of creating a means of fastening something to a workpiece. They are usually used with wood or metal, which can be tapped into using the self-tapping end of these bolts. The remaining thread can then be used to attach something to the workpiece by means of a nut or something else with an internal thread.

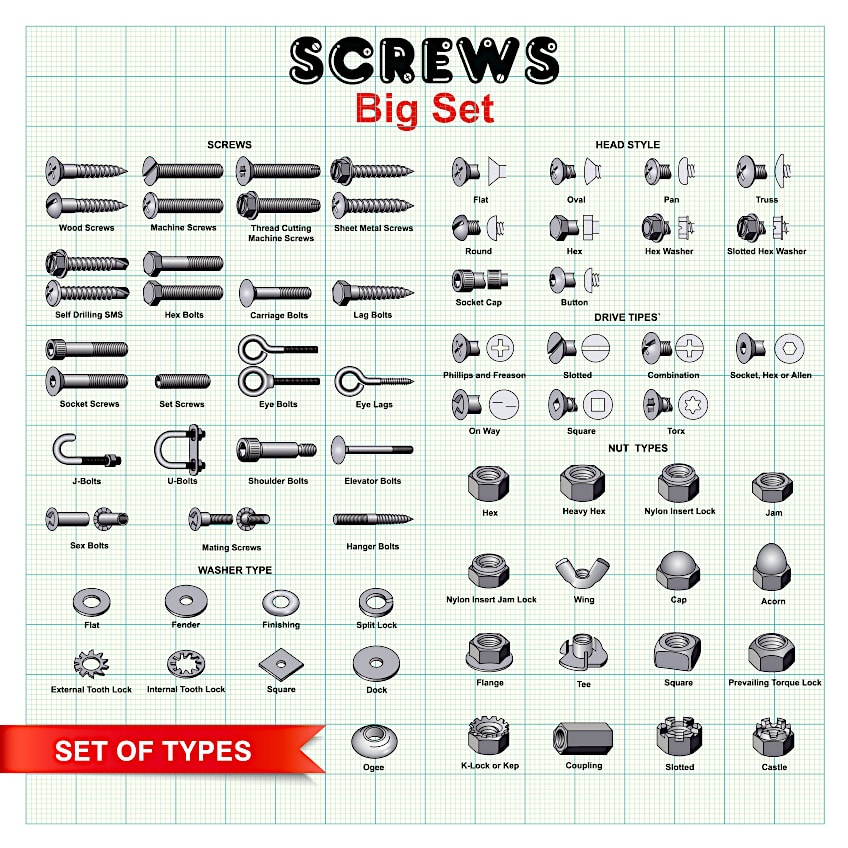

Chart of Types of Screws

While it might take you a while to read through some of the information above, we have put together a chart of types of screws you might encounter as well as their applications and drive configurations for your convenience. Always ensure that the material you’re working with is capable of accepting the bot/screw type you intend on using a given fastener with.

| Type of Fastener | Drive Configuration | Application |

| Wood Screws | ● Phillips ● Slotted | Wood fastening |

| Machine Screws | ● Phillips ● Slotted | Metal fastening |

| Threaded Cutting Machine Screws | ● Star ● Slotted ● Hex External | Wood and metal fastening |

| Sheet Metal Screws | ● Phillips ● Slotted | Metal fastening |

| Self-Drilling SMS | ● Hex external ● Phillips | Metal and wood fastening |

| Hex Bolt | ● Hex external | Metal and wood fastening |

| Carriage Bolt | ● Hex external | Metal fastening typically undercarriages |

| Lag Bolt | ● Hex external | Wood and metal fastening |

| Socket Screws | ● Hex internal | Primarily metal fastening |

| Set Screws | ● Hex internal | Metal fastening and mating surfaces |

| Eye Bolt | ● Hand tighten ● Hex spanner with nut | Concrete and brick fastening |

| Eye Lags | ● Hand tighten ● Hex spanner with nut | Wood and metal fastening |

| J-Bolt | ● Hand tighten ● Hex spanner with nut | Metal fastening primarily |

| U- Bolts | ● Hand tighten ● Hex Spanner with nut | Pipe and hose fastening |

| Shoulder Bolt | ● Hex internal | Dowel and pin replacement as well as wood and metal fastening |

| Elevator Bolt | ● Hand tighten ● Hex spanner with nut | Metal fastening under load |

| Sex Bolt | ● Slotted | Metal fastening for security applications |

| Mating Bolt | ● Slotted | Metal fastening for security applications |

| Hanger Bolt | ● Hand tighten ● Hex spanner with nut | Wood and metal fastening |

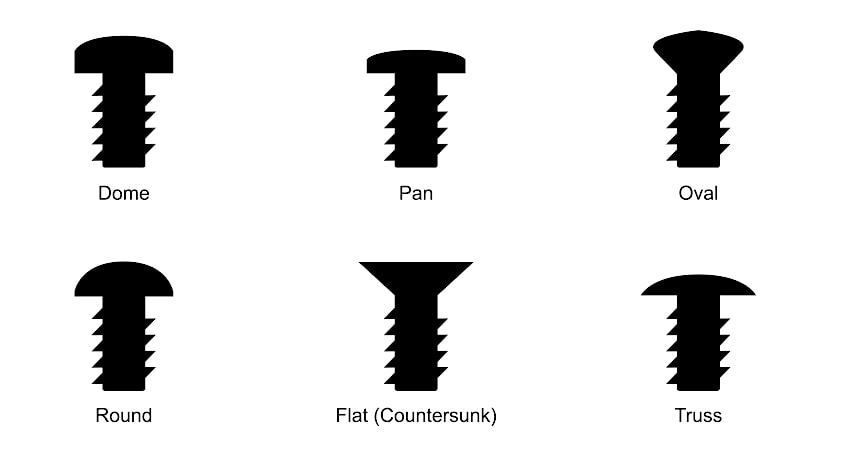

Common Bolt and Screw Head Types

If you’re going to be dealing with bolts regularly, it’s a good idea to familiarize yourself with some of the head types you might come across on your journey. Bolt heads have been developed and refined over decades to suit different applications, therefore you should do some planning and even some experimentation, if possible, to determine which head type is best for your workpiece. Also, remember that the head type refers to the shape of the head visible from the user’s end of the bolt and not the drive configuration nor thread-facing shape.

Flat Head

Different types of screws and bolts are used for different applications, and as the name suggests flat head screws are designed for fit applications where a flat head is needed. Flat head bolts and screws are usually countersunk and used in applications where the surface needs to remain as flush as possible. These are usually used in woodworking as the drive configuration can easily be filled with wood filler, or in machinery where the surface area must remain unobstructed.

Oval Head

While different types of screws and bolts are made to fit the material and the surface from which they will go into or protrude out, oval head screws don’t really fit any of these scenarios. Oval head screws and bolts are slightly domed so they’re easier to install and remove. They are also countersunk like flatheads but are less likely to have their drive configurations stripped upon removal.

Bugle Head

Bugle head screws are the type that you can pick up at your local hardware store in a pack of 100 or more. They’re the go-to screw type for woodwork and ensure that the surface doesn’t take any damage upon installation. This screw type is also used with surfaces like drywall as they’re self-tapping and can be installed with a screwdriver if need be.

Binding Screws

Binding screws, or Chicago screws are basically the same design as sex bolts and mating bolts. They fit into one another from the opposing sides of a surface and are unique among fasteners. These screws are typically found holding together leather binders as they do not cause any damage to the surfaces they’re used on (they’re super smooth).

Domed Head

Domed head screws are found all over the place because they’re so useful. They can be found mainly in the automotive and upholstery industries thanks to their ability to class-up pretty much anything they’re used on. How do they do this? Well, they’re shiny and small which makes them easy to hide, and even if you aren’t able to hide them, they complement any workpiece nicely.

Flange Head

Although flange head screws are typically made with an external hex configuration, they can be found in both the Phillips and slotted configurations too. These types of screws function as retainers thanks to their built-in flanges, which means you don’t need washers or any additional fasteners to help bite into the surface of your workpiece in order to secure it.

Truss Head

Screw types and sizes are virtually endless, and the chances are that you’ll only learn about a certain screw type when and where you need it. Truss head screws are one of those, they have a head with a large diameter, and the head is domed close to the drive configuration while the outer edges are flat. This screw type is used on thin metal surfaces to prevent it from being pulled through.

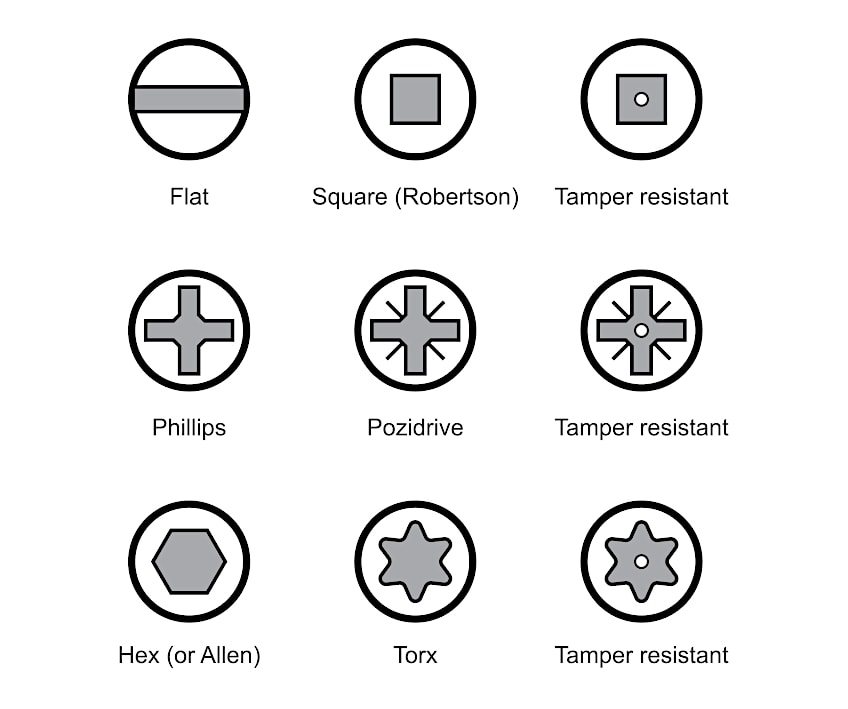

Drive Configurations

What is a drive configuration? Put simply, this refers to the shape on the head of a bolt or screw which indicates which tool you will need to secure it. Some of the most common drive configurations are slotted and Phillips, but there are other drive configurations that have been specifically designed to prevent theft and/or tampering. Let’s have a look at a few of the common and not-so-common drive configurations.

Hex Configuration

Hex configuration bolts are pretty common in everyday applications. They are designed to be used in applications where a lot of torque will be applied to the fastener. These bolts are used on machinery, cars, motorcycles, computers, and even furniture. These bolts are easy to work with and pretty difficult to strip. They are available in hex external which can be attached and removed with a socket, or hex internal which requires the use of a hex spanner otherwise known as an Allen key.

Phillips Configuration

This is arguably the most common type of drive configuration you will come across in your lifetime. These are used in pretty much every application in every industry around the world, and even somewhere they shouldn’t be! These are characterized by their four-pointed star-like recess which a Phillips head screwdriver or attachment can be used to install and remove.

Pozidrive Configuration

Pozidrive is less common than Philips head configurations, but they are used for what are essentially the same applications as Phillips. They can be tough to distinguish from one another but if you simply look closely at the head, you’ll notice that pozidrives have extra recesses located in the corners of the Phillips configuration star. You might be able to use a Phillips head screwdriver to install and/or remove these depending on the depth of the recesses.

Quadrex Configuration

Quadrex is sort of a combination drive configuration, although it might be more accurate to say that it’s a sort of hybrid between the Phillips head configuration and the square recess one. Instead of the stared points of the Phillips head configuration the tips of the stars on this drive are squared and require a squared Phillips head to install and remove.

Slotted Configuration

Besides the Phillips head configuration, this is one of the most common types of drive configuration you will encounter in your lifetime. When they are worn out, they aren’t the most reliable, but because they’re cheap and easy to manufacture and install they’re pretty popular. They can be installed and removed using a flat screwdriver and are great for small, casual work.

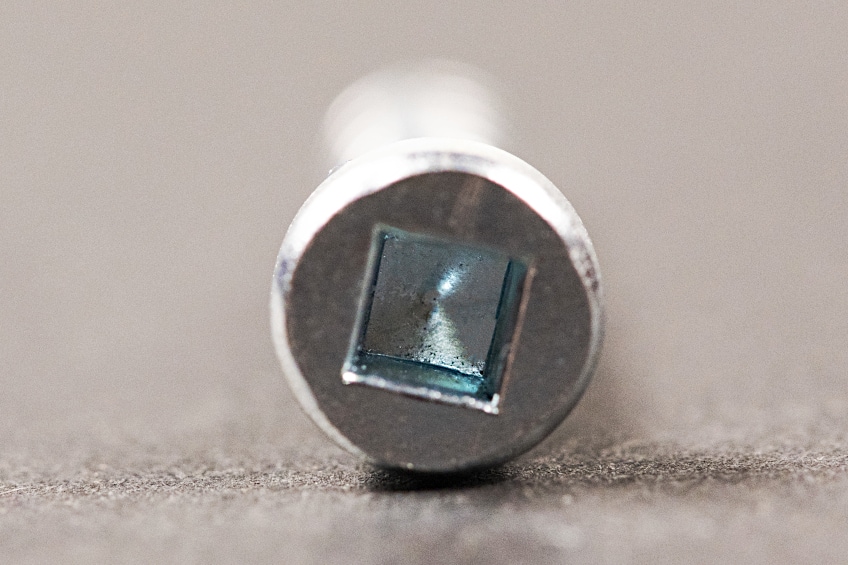

Square Recess Configuration

Square recess configurations are not super common these days but they’re pretty cool and are really consistent in their ability to be installed and removed without stripping the drive. They are referred to commonly as Robertson heads and can be installed and removed with a square head tool which is found in most quarter-inch ratchet sets.

Star Configuration

Star drives are weird but really useful and are great for applications where the fastener will be installed and removed regularly as they prevent overtightening. They are a combination of what is essentially two Robertson squares, which means they’re easy to work with. These can be installed either with a star-shaped drive or a Robertson square, but for higher toque applications we recommend using the intended tool.

TORX Configuration

TORX screws are something that everyone has seen but until recent years not many people have actually used them thanks to other drive configurations being more convenient. They’re essentially a six-pointed star recess which is commonly used on electronics. They can be installed and removed via the use of a TORX drive.

Tri-Wing Configuration

If you’re thinking to yourself that this configuration resembles a conventional Phillips configuration with extra steps, then you’d be right. This is actually a fairly new invention of the Phillips screw company and required a new kind of tool to install and remove. This configuration is designed to last longer and prevent stripping of the drive configuration (cam-out).

Tamper-Resistant Drive Configurations

While most drive configurations are meant to simply be easy to install and remove, others are meant to be easy to install and challenging (if not impossible) to remove. Tamper-resistant drive configurations can be found wherever security and/or theft is a concern, so let’s have a look at some that you might come across.

Pin Star Configuration

While the star-shaped drive configuration might be enough for some to discourage theft and tampering, the pin drive configuration takes things just one step further. Inside the recess of the star is a pin that protrudes upwards preventing the use of anything other than a specialized tool from being used to install or remove this fastener.

Sentinel Configuration

While the pin star configuration might be challenging to remove, the pin star configuration is virtually impossible to remove once it has been installed. That’s right, this screw type can only be used for permanent installation unless you intend on using a drill bit to remove it, in which case you’re likely to damage your workpiece too!

Two-Hole Configuration

This one is pretty straightforward. It’s a countersunk flat head with two holes instead of a conventional drive configuration. It’s a simple yet highly effective way to deter tapering as there aren’t any common tools that can be used to substitute the special tool needed to both install and remove this fastener.

Now that you know of some of the most common screws and bolts you’re likely to encounter, what some of these screws and bolts can be used for, which tools are needed to install and remove them from a surface, as well as which fasteners you can use to deter theft and/or tampering, it’s time for you to get out there and put your new-found knowledge to the test. Remember to avoid cam-out and stripping your bolts and screws but work patiently and always use the correct tool for the job.

Frequently Asked Questions

How Do You Prevent Stripped Screws?

The best way to prevent a stripped screw is to use the correct tool for the job and to work as methodically as possible. It’s also best to ensure that your tool is perfectly straight to avoid camming out, and of course to use your experience to ensure that you do not strip the thread of your bolt/screw. Also, ensure that you know the torque tolerances of your fasteners.

How Do You Remove a Stripped Screw?

A stripped screw can be a nightmare no matter what the job is. Removing one can be a bit daunting too but not impossible. There are stripped screw extractors that can be used to extract stripped screws, or if your workpiece and material allow it, you can use a drill bit to tap a hole into and remove the stripped screw/bolt.

How Do You Choose a Screw Head’s Material?

Just as you have likely chosen the material your workpiece is made of, you should choose the correct material for your fasteners as well. If your workpiece will be situated outdoors choose metals that are resistant to the effects of the elements, and if your workpiece needs to shine aesthetically, choose fasteners that can be polished and/or painted over.